How Long does Wood Glue take to Dry? Tips for Quick Drying

Wood glue is a commonly used adhesive in woodworking projects, and It’s crucial to wait until your wood glue has fully cured before continuing with your project. Whether you’re making something new, fixing a wooden toy, or making repairs to a piece of furniture, the amount of time it takes for wood glue to cure depends on the kind of glue, temperature, and humidity.

Wood glue typically consists of a water-based emulsion of polyvinyl acetate (PVA), which forms a strong bond between two pieces of wood when it dries. Several kinds of wood glue are available, including yellow glue, white glue, and polyurethane glue.

This guide will cover why wood glue is strong, different wood glue dry times, what factors influence its drying time, and a few disadvantages of wood glue. After reading, you will have a better understanding of wood glue. So let’s dig in!

Table of Contents

Understand the difference between Drying and Curing

Drying and curing are related, but distinct processes occur after an adhesive, such as wood glue, is applied.

Drying time typically refers to the period during which the adhesive has dried to the point that it is no longer wet or tacky to the touch and the joint is secure enough that you can remove clamps or perform other work on the project.

However, during the drying process, the adhesive is still undergoing a chemical reaction as it cures. It may take additional time for the adhesive to cure and reach its maximum strength fully. Once the curing process is complete, the bond will be fully secure and safe.

It’s important to note that an adhesive’s drying and curing times can vary depending on the type of adhesive, the materials, temperature, humidity, and other environmental factors.

It’s always best to follow the manufacturer’s instructions; they typically provide correct information for drying timeframes.

Average Wood Glue Dry Time

The drying time of wood glue can vary depending on factors such as the type of wood, the temperature, humidity, and the specific kind of glue. While some wood glues may dry to the touch within 10 to 30 minutes, the drying time can also be longer, particularly in cool or humid environments.

However, make sure to distinguish drying and curing times. Drying time is faster, but curing can take up to 24 hours.

Different Types of Wood Glue: How Long they Typically Take to Dry

There are several options available on the wood glue market. Each of these goods has advantages and disadvantages that can make or break your experience. The drying times of the various types of wood glue also differ.

Cyanoacrylate wood glues, also known as CA, are typically the quickest drying of all kinds, setting in only a few seconds. Additionally, they heal quickly and reach full strength in just eight hours.

PVA wood glue, also known as polyvinyl acetate, dries more slowly and takes 10 to 15 minutes to set. The complete hardening and curing of these glues could take longer than 24 hours.

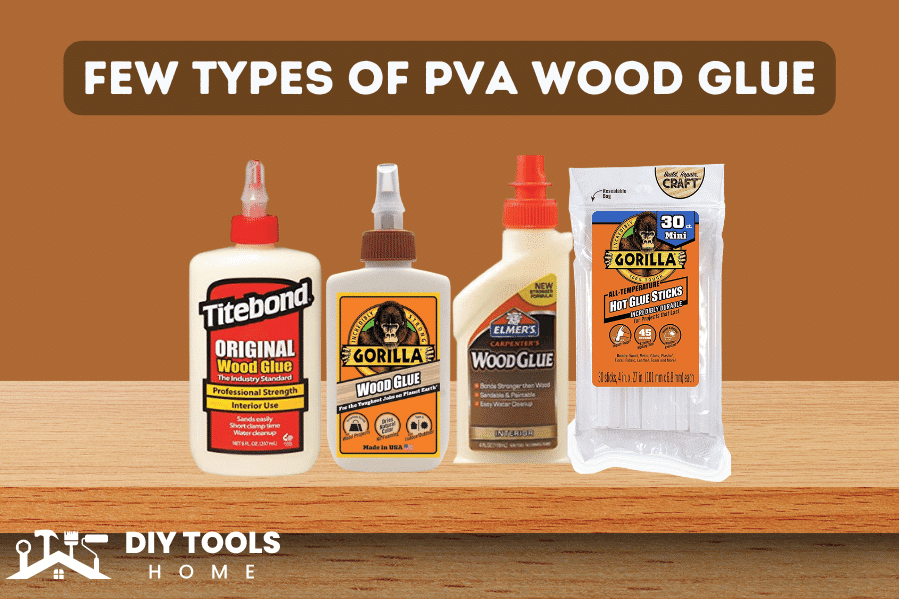

Polyvinyl acetate (PVA)

The most frequently used wood glue and often seen is the acronym PVA. It stands for polyvinyl acetate, a synthetic rubbery polymer used to produce carpenter’s glue or wood glue. A few types of PVA wood glue are Gorilla Glue, Titebond Glue, hot glue, and Elmer’s wood glue.

It’s a general-purpose woodworking glue that can be secured for as little as 30 minutes and dries entirely after around 24 hours.

1. Titebond

It is for interior projects like furniture, cabinets, tabletops, etc. It produces a more powerful bond than the wood it adheres to.

Titebond Drying Time

Titebond usually dries in 30 to 60 minutes, and its curing time is 24 hours. Titebond recommends clamping the materials together while making sure stressed joints are attached for 24 hours.

2. Gorilla Wood Glue

Gorilla wood glue is likely the most well-known all-purpose adhesive. Gorilla Wood Glue is a durable, water-resistant product ideal for indoor and outdoor use that provides a robust and quick bind across various wood surfaces.

Gorilla Wood Glue combines the advantages of a water-based PVA glue with Gorilla’s well-known holding power. You may be sure that the binding line on your projects will be spotless because it dries a natural color.

Gorilla Wood Glue Drying Time

Gorilla Wood Glue takes much longer to dry than standard Gorilla Super Glue. This happens because wood glue always requires longer to dry than other types of glue. The drying period for Gorilla wood glue is 24 hours. It is crucial to apply consistent pressure to the objects as they dry by clamping them together.

3. Hot Glue

Hot glue also names as hot melt adhesive. It comes in the form of a stick which you need to heat through the hot glue gun’s nozzle. Most woodworkers don’t use hot glue due to their propensity to melt and revert to liquid when heated.

Hot Glue Drying Time

Depending on the adhesive used, hot glue might set in less than a minute. The glue typically takes about five minutes to cure and solidify fully.

4. Elmer’s Wood Glue

It is a popular synthetic PVA-based glue. It is widely used in homes, businesses, and schools and effectively bonds most materials, such as wood, paper, and fabric.

Elmer’s Wood Glue Drying Time

Elmer’s website claims that their glues “dry fast and clear.” Although they do not give the exact time length it takes for the adhesive to finish drying. Elmer’s glue will typically take around 24 hours to dry completely. However, this can change according to the environment’s temperature and humidity levels and how thick the adhesive layer is.

If you need your item to dry quickly, you can do a few things. Instead of using a thick layer of adhesive, start using a thin one.

Why is wood glue so strong?

Do you think wood glue is stronger than the wood it binds? Simply the answer is yes because the glue itself is strong by nature. During the application and dying process, wood glue absorbs and becomes part of the wood.

The strength of glue combined with wood is greater than that of wood alone. It’s simple math. Whether it’s a project for a house or something else entirely, the quality of the finished product makes the work of gluing and the drying period well worth it.

What are the disadvantages of wood glue?

Disadvantages of Wood Glue

While wood glue is a popular and effective adhesive for woodworking projects, there are a few disadvantages. These include:

1. Weak end grain connections in wood.

2. Wood glue is only suitable for use with wood and wood items.

3. Some types of wood glue you can only use indoors, away from sources of moisture.

4. The use of eco-wood is very high. It may be difficult to remove.

5. Another drawback of wood glue is its time frame to dry out completely.

Factors Influencing Wood Glue Drying Times

Now you know about different types of wood glue and their drying times. Certain factors slow down the drying period. Next time you are using wood glue, keep in mind these factors to fast your process.

1. Assembly factors

Drying time varies with the assembly factor. There are two types of assembly to consider while working with wood. This element will either speed up or slow down the drying process.

Open assembly

This is the period from when the glue pours out of the bottle until you can no longer utilize it.

Close assembly

Close assembly specifies how long you can move the bond until you can no longer do so. Some wood glues take longer to dry than others, and some need to apply so quickly before it’s too late to use them.

2. Temperature

Any drying process depends on temperature, which is considered a crucial factor. In high-temperature settings, most wood glues will dry more quickly, setting and forming the needed strong connections in the shortest amount of time.

Conversely, low temperatures may make you wait longer because wood glues tend to dry slowly in these conditions. High temperatures can speed up the drying of wood glues, but they can also melt some types of glue if the temperature rises too high.

3. Humidity

Humidity is one of the main factors that affect drying times for paint, concrete, or wood glue. High-humidity situations are characterized by more moisture in the surrounding air, preventing the glue’s water from evaporating.

Although the glue will finally set and cure, the process will take a long time because it will struggle. The more moisture is present in the air, the greater the humidity.

The moisture in water-based glue can evaporate less readily in the humid air. Some adhesives like PVA get dry faster than in moist air.

4. Moisture

Moisture problems that come from wood are attached. If the wood is damp or has any moisture, it slows down the drying process of glue. The wood is frequently the source of the moisture issue.

If the wood is damp or contains any moisture, it will slow the drying process of glue. Usually, the wood adhesive dries by releasing its water into the air and through the wood.

5. Type of wood

The wood is mainly of two types, i.e., softwood and hardwood. It describes how tough lumber is. Balsa is very light and easy to glue while botanically a hardwood.

Softwood-like pine boards have an open structure and proliferate. They more readily absorb glue and bond quickly. Hardwoods grow more slowly and dense, so glue takes longer to penetrate.

6. Ventilation

The circulation of air is another critical factor in the drying process. Air circulation makes it easier and more time-consuming for the glue to maintain its moisture content. More air means more water molecules get swept up, resulting in a faster drying process.

A lack of flow will make the drying take longer. It can even stop it from happening in other situations, which can completely derail a project. Choose an open area to work in for such projects; if it’s not possible, open doors and windows.

Tips to speed up the drying process

1. Apply some Heat

If the weather is not hot, apply heat to speed up the drying process and finish your project in less time. Use a hairdryer on the glued area, switch on a space heater, or use your home air conditioning system to raise the temperature.

2. Use less glue

The thicker layer of glue will take more time to dry. Using less glue will ensure a quick drying process. You can use glue bottles to spread the glue while woodworking projects.

3. Use a dry piece of wood

A dry wooden piece absorbs glue easily and quickly; moisture from the glue usually evaporates straight into the air. The water particles from the glue won’t be able to flow through the wood if it is already soaked with moisture.

This will slow the drying process. Using dry wood will provide the water particles enough room to escape, hastening the drying of the wood glue.

Conclusion

Wood glue is the main component of carpentry and woodworking projects. Reading the instructions is essential, besides knowing the factors like temperature, moisture, etc., that affect dry time. It is also necessary for you to understand the drying time to make sure the joints between two pieces of wood are strong for years.

Knowledge is essential in ensuring better results. We hope you found this article helpful in using wood glue and making your next project boom.

We also have well-researched guides for you on other DIY tools. Let’s explore and learn!

See Also:

How to read a Tape Measure? Expert Tips for Better Measuring

How to use a Combination Square for Accurate Measurements?

FAQs

How Long Should You Clamp Wood Glue?

Major manufacturers like Titebond and Elmer’s suggest clamping an unstressed wood glue joining for 30 to 60 minutes. However, stressed joints require a longer clamp time for wood glue, frequently up to 24 hours. To keep the boards in place, don’t put any stress on the new joint for at least 24 hours.

Are 12 Hours Enough For Wood Glue?

Drying typically takes 10 to 30 minutes, depending on the type of wood, temperature, humidity, and wood glue. However, keep drying and curing times the same. While drying takes less time, curing can take up to 24 hours.

Does Wood Glue Dry Faster In Hot Or Cold?

In most situations, PVA and polyurethane wood glue are the best options; in most cases, both are impacted by the air temperature. Below 45 to 50 degrees Fahrenheit, they typically won’t dry correctly.