How Much Weight Can Wood Glue Hold?

Wood glue is an essential ally of every woodworking project. It is made from a combination of water, resin, and a bonding agent to make wood joints more robust and helps them tolerate stress. But just how much weight can wood glue hold? Many woodworkers and engineers ask this question. But its answer is more complex.

The strength of a wood glue bond depends on various factors, like the type of wood you are using, the quality of the glue, and the conditions in which you make the bond. In general, wood glue can hold a significant amount of weight, up to 4,000 pounds per square inch of bonded area.

This article will help you to explore how much weight different types of wood glue can hold, how various factors could influence the bond’s strength, and much more!

How Much Weight a Wood Glue Can Bear?

The strength of wood glues is measured in PSI. PSI (Pounds per Square Inch) is a unit that shows the tensile strength of wood glues. Let me explain it with an example. For example, if you apply any wood adhesive to join the two pieces of wood after they get completely dried, you try to pull the pieces off; the glue with the highest PSI unit will require more strength to separate.

The force you apply to pull the pieces off is the stress or pressure measured in PSI. In the past ten years, wood glues have become more advanced and more robust. Most types of wood can tolerate forces between 1000 PSI and 2000 PSI, but wood glues can bear pressures between 3000 PSI and 4000 PSI.

Key Ingredients That Make the Wood Glue Strong

The question that comes to mind when we are studying wood glues is why wood glues are even more potent than wood. Here are some key elements that make the wood glue more robust.

- Polyvinyl Acetate Emulsion: It is a rubbery solid polymer in almost all wood glues.

- Polyurethane Prepolymers: It is a potent and long-lasting ingredient of wood glue. These polymers provide more stability to wood glue. The popular polyurethane-based wood glue is Gorilla Glue.

- Homologues: This ingredient comes from animal tissue. Homologous chemicals are added to wood glues to enhance their binding strengths.

Strength Values for Some Wood Glues

The strength values for wood glues typically range between 2000 PSI to 4000 PSI, meaning they can hold a pressure of up to 2000 to 4000 pounds per square inch. Let’s go through the tensile strength of some wood adhesives.

1. Gorilla wood glue

Gorilla wood glue has polyurethane polymers. If you are looking for the strongest wood glue, consider Gorilla Glue because it can bear pressure up to 3900 to 4000 pounds per square inch. It is the best glue for cabinets.

2. Epoxy Wood Glue

Epoxy wood glue is also the strongest glue; it can bear a pressure range between 3000 PSI to 4000 PSI. This glue is best for projects that bind wood to other materials such as mirrors, metals, etc.

You can use this long-lasting and robust glue if you are doing projects i-e

- Require a strong binding.

- It involves binding wood to other materials.

- Require more water resistance, e.g., for outdoor projects.

3. Polyvinyl Acetate Glue

The most common wood glue available and often used is PVA or Polyvinyl Acetate wood glue. It can bear pressure between 3000 and 4000 PSI. It is a type of wood glue that provides excellent strength along with water resistance. It dries quickly, so it’s an easy-to-use glue.

You can use this glue:

- For joining the wood joints

- On porous materials

- For projects that involve wood to wood or wood joining to other porous materials

- For the woodwork that needs a short drying time

4. Super glue

Super glue is also known as crazy glue. Its name is cyanoacrylate glue. Its tensile strength ranges between 2600 and 3600 PSI, so that it can deliver this much strength.

You can use Cyanoacrylate glue for

- The projects that require more strength within two different surfaces

- The works that don’t involve wood.

- The small crafting projects.

5. Hide glue

It is ideal for projects that require some flexibility and can bear stress around 3200 PSI. It is lessintense than other wood glues.

Glues Strength Table

All the above-mentioned tensile strength values for different types of wood glues are summarized here for your ease. Remember, the higher the tensile strength value, the more weight and pressure a wood glue can bear.

| Sr. no | Name | The pressure it can bear |

|---|---|---|

| 1. | Gorilla wood glue | 3900 to 4000 PSI |

| 2. | Epoxy Wood Glue | 3000 to 4000 PSI |

| 3. | Polyvinyl Acetate Glue | 3000 to 4000 PSI |

| 4. | Super glue | 2600 to 3600 PSI |

| 5. | Hide glue | 3200 PSI |

Factors That Influence the Holding Power of Wood Glues

When you use wood glue, some factors can affect the holding capacity of the bond. Try considering these factors to avoid any inconvenience.

1. Type of wood glue

It matters which kind of wood glue you are using. There are many glue types, and some are stronger than others. Your project usually doesn’t require high-strength wood glue, so check before using glue. Mainly people use PVA-based adhesives because they are easygoing.

2. Type of wood

If you are working on wood containing high oil content, it can interfere with glue working and will make weaker joint bonds. Examples of high-oil-containing woods include maple, oak, teak, etc.

Wood Glue Hack: Try using less water content, such as polyurethane-based glue.

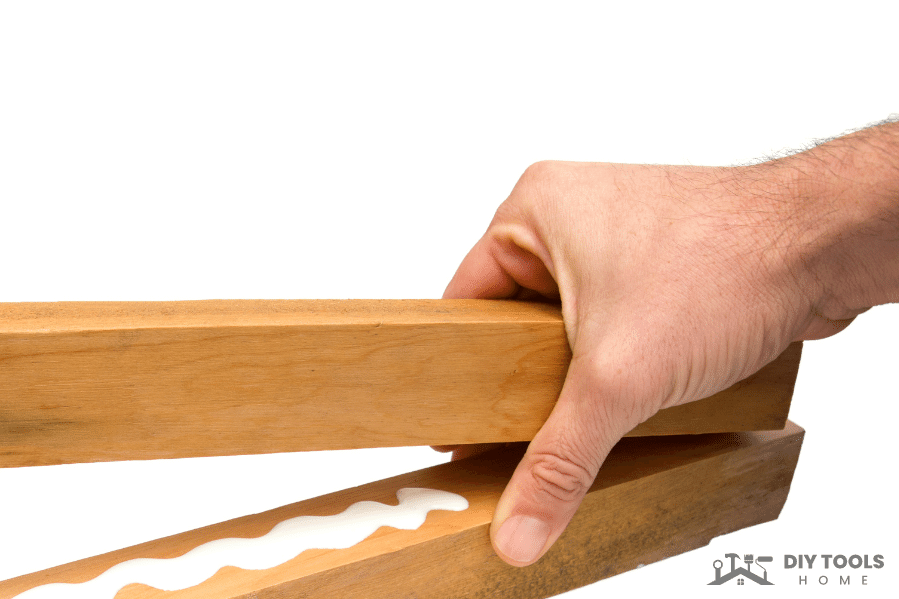

3. Clamping pressure

Clamping pressure is another factor that affects the wood’s strength. Using the optimum clamping pressure will overcome the initial resistance of glue and make it a thin layer that is effective for strong bonding.

Tip: For clamping softwoods, try using 100 to 150 pounds per square inch (psi) pressure and 175–250 psi for hardwoods.

4. Temperature and humidity

The temperature and humidity of your woodshop or working area matter a lot. They can affect the overall glue strength. You must ensure that you follow the proper instructions on the pack.

Tip: You can heat your working area during winter to work smoothly

Standard Strength Tests Used for Wood Adhesives

Tests on adhesives or glues are applied to check whether the bond suits its particular function. Adhesives encounter many stresses and pressures during life, so performing these tests is safe.

American Society for Testing Materials (ASTM) has specified different tests for checking adhesive strength. Some of them are as follows.

- ASTM D4317 is the standard testing method used for Polyvinyl acetate based wood glues

- ASTM D2339 is the standard test method used to measure the strength properties of glues for two-ply wood types under stress.

- ASTM D2559 standard covers adhesives in woodworking projects requiring high strength and long bonds.

ASTM D638 Test

Although this test is not specific to the adhesives that bond the wood together. It is used to measure the tensile strength of plastics. Still, we can also use this test to check the tensile properties of wood adhesives. This test measures the maximum force required to break the bond.

Making Glue Bond Stronger- Additional Tips

Try considering these tips to work more smoothly.

Key highlights

Conclusion

Wood glue has become an essential tool for carpenters. They prefer to use wood glue in comparison to screws. It joins the wood pieces, makes the wood joints more robust, and helps them tolerate stress.

Regarding how much maximum weight it can hold, it depends on the strength of the wood glue and the wood type. Therefore, it is crucial to consider the properties of both the adhesive and the wood when determining a joint’s weight-bearing capacity.

FAQs

Is Wood Glue Strong Enough To Hold Wood Together?

When you apply the wood glue correctly, it is strong enough to hold the wood together. It’s even more vital than screws because it can fix the whole wood joint, while screws only fix a specific location.

What Is The Best Wood Glue To Hold Weight?

Due to its high tensile strength, many woodworkers rely on Gorilla Wood Glue. This Polyvinyl Acetate glue dries up fast, giving a stronger and more durable bond. Use it for interior and outdoor woodwork.

Is wood glue stronger than wood?

In one line, the wood glue is stronger than the wood. If you look at the tensile strength values for the wood and wood glue, the wood glue has higher tensile strength values ranging from 2000 to 4000 PSI, while Woods’s tensile strength value ranges between 1000 PSI to 2000 PSI.

Is There Any Glue That Can Hold A Weight Of Up To 150 Kg?

Yes, the Araldite Super Strength epoxy glue can hold up to 150 kg weight. It has a high water-resisting ability and forms bonds on many surfaces, such as wood, steel, metals, ceramics, fabrics, rubbers, and plastics.